-

1 member led by xiaoshan rongliOver time, more functional fabrics will emerge as the research continues to deepen.

-

1 member led by xiu uminThe production for Household Product Mould https://www.furnituremould.com/ is a very rigorous process. Next, we will specifically talk about the steps of production for household product mould:

1. Prepare plastic materials. The brand-new plastic raw... more -

1 member led by Gete cecilThe demand for BOPP labels https://www.print-labels.net/product/plastic-labels/bopp-labels.html is very large, and a large number of labels need to be printed every day. So, what should be considered when printing BOPP labels?

1. The length of... more -

1 member led by xi xiximinThe digital printing fabric https://www.wanshiyitex.com/product/digital-printing-fabric/ are gradually popular, and the printed fabrics produced by digital printing are more realistic and precise than traditional printing. At present, there are mainly... more

-

1 member led by xiaoshan rongliWhat are the advantages of latex mattresses?

-

1 member led by xiaoshan rongliIn fact, the quality of sleep depends on deep sleep, and under the premise of ensuring light and dark and odorless, the most direct factor affecting sleep is the hotel mattress used for sleep.

-

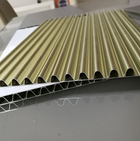

1 member led by Jia lubang1. High strength and rigidity to bear weight

The Aluminum Honeycomb Panel https://www.alubang.net/product/aluminum-honeycomb-panel.html has ideal stress distribution for shearing, compressing and stretching. Aluminum honeycomb panels can be made of very... more -

1 member led by xiu uminThe service life of Air Cooler Mould https://www.furnituremould.com/products/water-cooler-mould/ is closely related to correct maintenance. In fact, too many dies are scrapped due to improper maintenance. The following summarizes some basic knowledge of... more